In the world of precision manufacturing, achieving complex shapes and precision cuts is a critical aspect of producing high-quality components. One method that stands out for its efficiency and accuracy is contract broaching. This specialized machining process has become the go-to solution for a wide range of industries seeking precision and consistency in their components.

What is Contract Broaching?

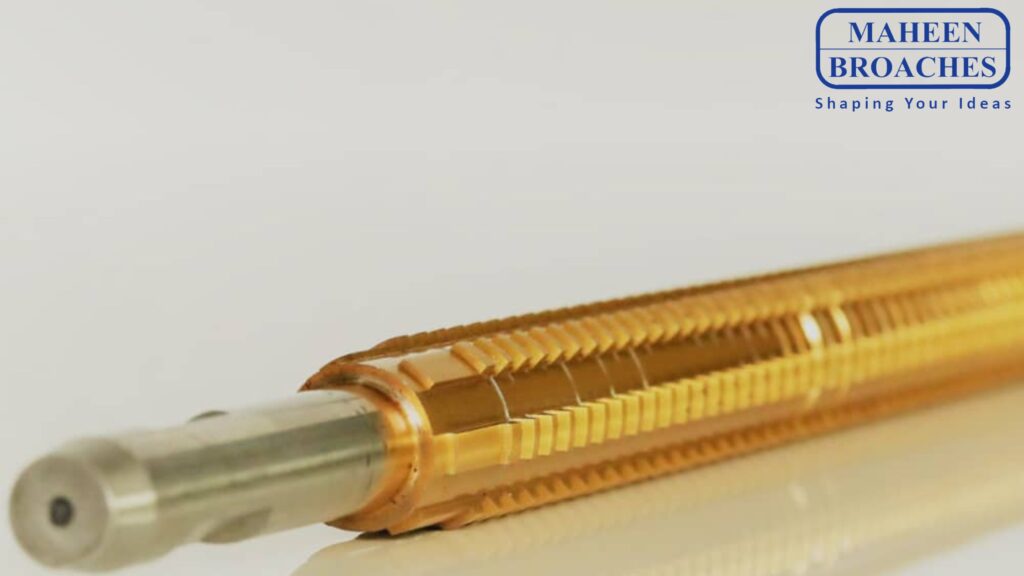

Contract broaching is a machining process used to create intricate shapes and precision cuts in metal, plastic, and other materials. It involves a tool called a broach, which has a series of teeth that gradually increase in size. As the broach is pulled or pushed through the workpiece, the teeth remove material in a linear motion, creating the desired shape. This process can be used for internal or external machining and is often employed to produce gears, splines, keyways, and other intricate features.

The Advantages of Contract Broaching

1. Precision and Consistency: Contract broaching offers unmatched precision and consistency in producing components. The use of specialized broaching tools ensures that every piece is machined to the exact specifications, minimizing variations and errors.

2. Time and Cost Efficiency: The broaching process can create complex shapes in a single pass, reducing machining time and cutting down production costs. Additionally, the high level of accuracy means less material waste, resulting in cost savings.

3. Versatility: Contract broaching can be used for a wide range of materials, from soft metals to hardened steels. This versatility makes it an ideal choice for various industries, including automotive, aerospace, defense, and more.

4. Enhanced Surface Finish: The linear cutting motion of contract broaching produces superior surface finishes compared to other machining methods. This ensures smoother and more aesthetically appealing components.

5. Consistent Quality: The use of automated broaching machines allows for consistent quality across large production runs. This is crucial for industries where precision and reliability are paramount.

Contract Broaching Services: The Key to Success

To harness the full potential of contract broaching, many companies opt to collaborate with specialized contract broaching service providers. These experts have the necessary machinery, expertise, and knowledge to deliver exceptional results.

Benefits of Outsourcing Contract Broaching Services:

1. State-of-the-art Equipment: Contract broaching service providers invest in advanced broaching machines and tooling, ensuring top-notch quality and efficiency.

2. Expertise and Experience: These service providers employ highly skilled technicians who possess a deep understanding of broaching techniques and can handle complex projects with precision.

3. Cost Savings: By outsourcing broaching services, companies can avoid the significant upfront costs associated with purchasing and maintaining broaching equipment.

4. Faster Turnaround Times: Contract broaching service providers are dedicated to delivering on time, allowing manufacturers to meet their production deadlines more effectively.

5. Customized Solutions: With a vast array of broaching capabilities, contract broaching services can cater to the specific needs of diverse industries and deliver customized solutions.

Conclusion

Contract broaching has emerged as a game-changer in the world of precision manufacturing, streamlining the production process and ensuring exceptional quality and consistency. Its ability to create intricate shapes, cost-effectively and efficiently, has made it a preferred choice across various industries. By partnering with specialized contract broaching service providers, manufacturers can harness the full potential of this machining process and stay ahead in a competitive market, offering products of superior quality and value.