Spline broaches play a crucial role in precision machining and are widely used in various industries. In this comprehensive guide, we’ll delve into the fundamentals of spline broaching, its applications, and why it’s a preferred method for creating intricate spline profiles.

What are Spline Broaches?

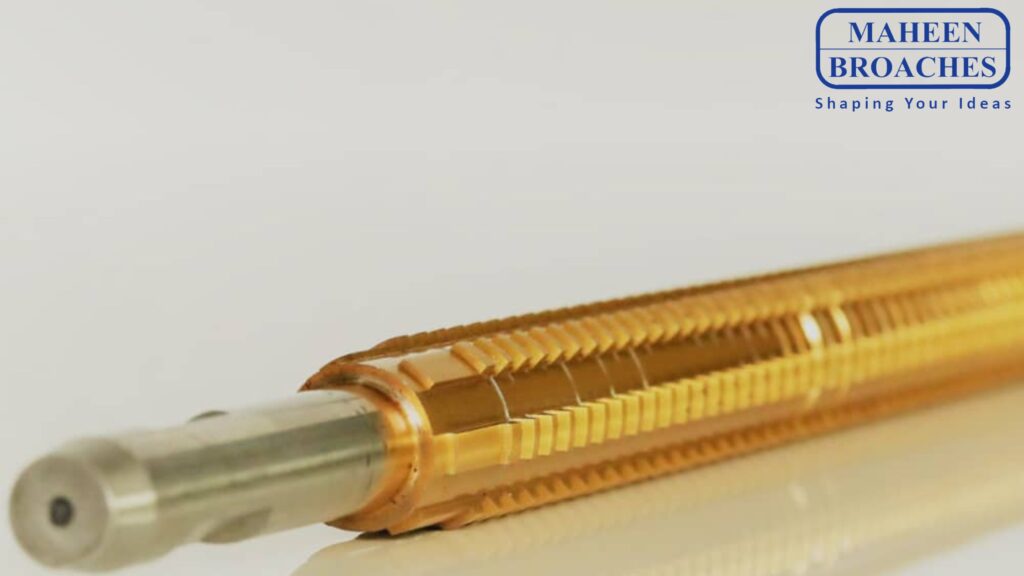

Spline broaches are cutting tools with a series of teeth that progressively increase in size. They are designed to create precise spline profiles on workpieces. Spline broaches come in various forms, including involute, straight-sided, and serrated, depending on the specific application.

Applications of Spline Broaching

Spline broaching finds applications in diverse industries, such as automotive, aerospace, and machinery manufacturing. It is commonly used to create gear-like teeth on shafts, hubs, and couplings. Spline broaches enable the production of complex shapes with high accuracy and efficiency.

Broaching Process

The broaching process involves pushing or pulling the broach through the workpiece to cut the desired spline shape. It is a versatile method that allows for both internal and external spline profiles. The cutting action is precise and produces excellent surface finishes.

Types of Spline Broaches

There are various types of spline broaches tailored to specific machining needs. Involute spline broaches are ideal for gear teeth, while straight-sided broaches are commonly used for automotive applications. Serrated broaches, on the other hand, are employed for special designs requiring unique profiles.

Advantages of Spline Broaching

Spline broaching offers several advantages, making it a preferred choice for many machinists. It provides high accuracy, repeatability, and efficiency in producing complex shapes. The process is cost-effective for large production runs and minimizes material waste.

Choosing the Right Spline Broach

Selecting the appropriate spline broach is essential for achieving optimal results. Factors like material type, spline design, and batch size should be considered. Working with experienced broach manufacturers can help ensure you get the right tool for your specific needs.

Maintenance and Care

Proper maintenance and care of spline broaches are crucial to prolonging their lifespan and maintaining cutting performance. Regular inspection, cleaning, and re-sharpening are essential practices to prevent premature wear and ensure consistent results.

In Conclusion

Spline broaching is a fundamental process in precision machining, allowing for the creation of intricate spline profiles with efficiency and accuracy. Understanding the different types of spline broaches, their applications, and proper maintenance are key factors in achieving successful machining operations.

Whether you are a seasoned machinist or a newcomer to the field, mastering the art of spline broaching will undoubtedly enhance your capabilities and contribute to the success of your machining projects.