Introduction:

In the dynamic world of Indian manufacturing, where precision is paramount, the choice of tools becomes a critical decision. Among these, straight spline broaches stand out as indispensable assets, playing a pivotal role in shaping components with accuracy. In this comprehensive guide, we delve into the nuances of selecting straight spline broaches, providing Indian manufacturers with the knowledge they need to elevate their precision machining processes.

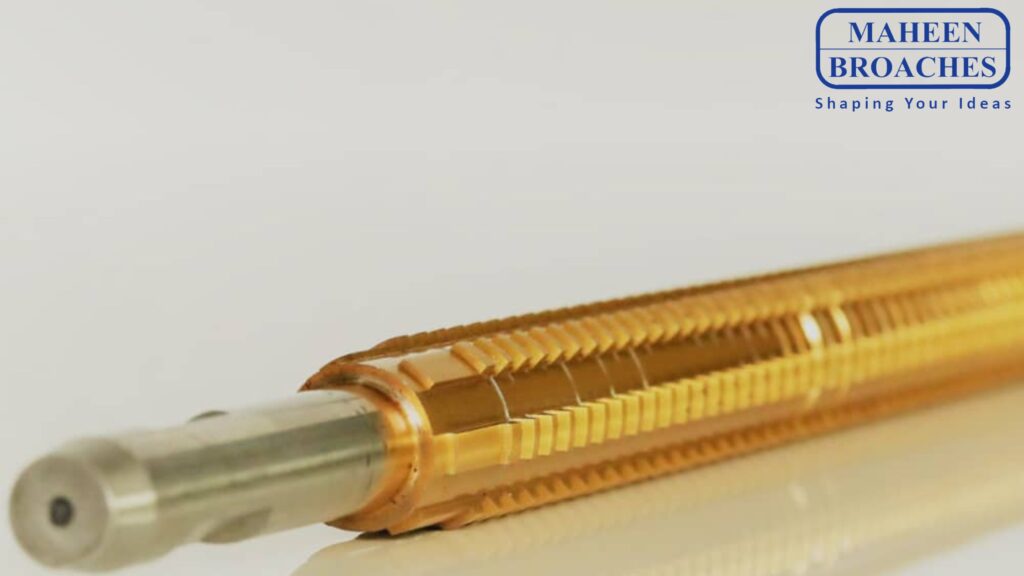

Understanding Straight Spline Broaches

Begin by introducing the concept of straight spline broaches, outlining their design, and explaining how they function in the manufacturing process. Emphasize the importance of straight spline broaches in creating precise splines on shafts, gears, and other components, setting the foundation for the reader’s understanding.

Types of Straight Spline Broaches

Explore the various types of straight spline broaches available in the market. Discuss key differentiators such as single-keyway, multi-keyway, and surface broaches, highlighting their specific applications and benefits. Provide practical insights into choosing the right type of broach based on the requirements of different manufacturing projects.

Material Considerations

Delve into the significance of material selection when it comes to straight spline broaches. Explain how the choice of materials impacts the broaching process, tool longevity, and overall performance. Offer guidance on matching broach materials with the workpiece material, ensuring optimal results for Indian manufacturers.

Coating Options for Extended Tool Life

Discuss the importance of coatings in enhancing the durability and performance of straight spline broaches. Explore popular coating options such as TiN, TiAlN, and diamond-like carbon (DLC), providing insights into their advantages and specific applications. Help manufacturers make informed decisions when selecting coated broaches for their machining needs.

Key Considerations for Tool Maintenance

Address the crucial aspect of tool maintenance to ensure prolonged tool life and consistent performance. Provide practical tips on proper storage, cleaning, and routine maintenance procedures. Stress the significance of regular inspections to identify signs of wear and address them promptly, preventing costly downtime.

Conclusion:

Summarize the key points discussed in the guide, emphasizing the critical role straight spline broaches play in achieving precision in Indian manufacturing. Conclude by highlighting how informed decisions in selecting and maintaining these essential tools can lead to improved efficiency, reduced costs, and elevated standards of quality in the competitive landscape of Indian manufacturing industries.