Introduction:

In the intricate world of machining and precision engineering, the art of serration broaching stands out as a crucial technique for creating precise and intricate designs on various materials. This comprehensive guide aims to unravel the nuances of serration broaching, providing manufacturers with valuable insights into its applications, benefits, and the impact it can have on enhancing the quality of their products.

Understanding Serration Broaching:

1. Precision in Every Cut:

Serration broaching is a machining process designed to create precise and uniform serrations on workpieces. These serrations, characterized by notches or grooves, serve various functions, from improving grip to enhancing the aesthetics of a product.

2. Applications Across Industries:

The versatility of serration broaching makes it applicable across a wide range of industries. From automotive components and cutting tools to consumer goods like knives and saws, manufacturers turn to serration broaches to achieve the intricate patterns required for optimal functionality.

The Serration Broaching Process:

1. Tooling and Equipment:

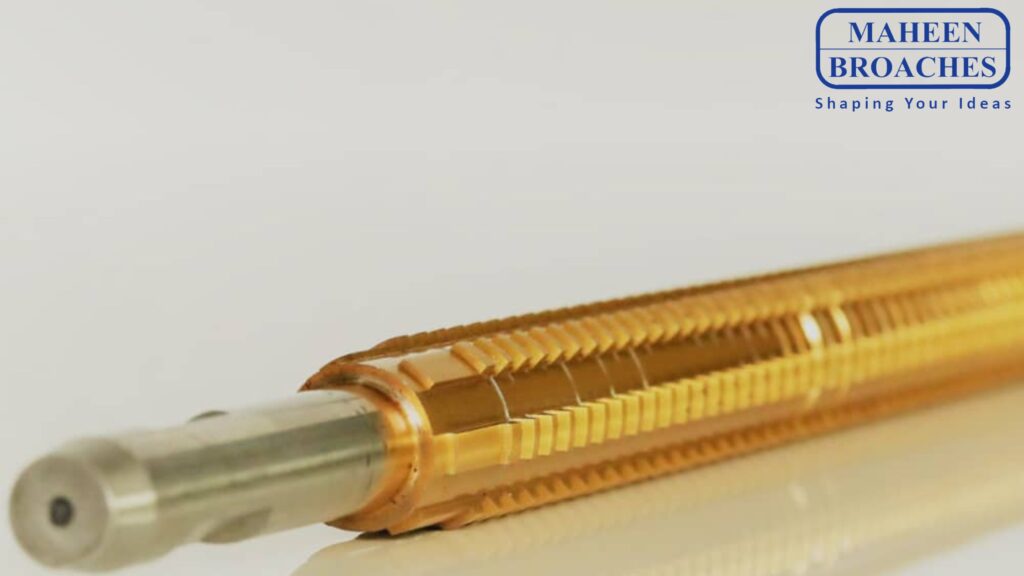

Serration broaching involves the use of specialized tools known as serration broaches. These broaches come in various designs, each tailored to create specific serration patterns. The process typically utilizes a broaching machine, ensuring precision and consistency in every cut.

2. Material Considerations:

Serration broaching can be applied to a variety of materials, including metals, plastics, and composites. The choice of material impacts the type of broach and machining parameters, emphasizing the importance of selecting the right tools for the job.

Advantages of Serration Broaching:

1. Enhanced Precision:

Serration broaching offers unparalleled precision, allowing manufacturers to create intricate designs with tight tolerances. This precision is crucial in industries where the functional and aesthetic aspects of serrations play a vital role.

2. Increased Efficiency:

The efficiency of serration broaching lies in its ability to produce accurate and repeatable results quickly. The process is well-suited for high-volume production, enabling manufacturers to meet demands without compromising on quality.

3. Versatility in Design:

Manufacturers can achieve a wide range of serration designs, catering to diverse applications. Whether it’s creating gear teeth, textured surfaces, or functional grips, serration broaching provides the flexibility needed to meet specific design requirements.

Considerations for Manufacturers:

1. Choosing the Right Broach:

Selecting the appropriate serration broach is crucial for achieving desired results. Factors such as material, serration design, and production volume should influence this decision.

2. Optimizing Machining Parameters:

Fine-tuning machining parameters, including cutting speed, feed rate, and depth of cut, ensures optimal performance and extends the life of the serration broach.

Conclusion:

Serration broaching stands as a testament to precision engineering, offering manufacturers a reliable method for creating intricate patterns and designs. As industries continue to demand higher levels of precision and customization, understanding the art and application of serration broaching becomes paramount. This comprehensive guide serves as a valuable resource for manufacturers looking to elevate the quality of their products through the mastery of serration broaching techniques.