In the intricate realm of manufacturing, precision plays a pivotal role in determining the quality and functionality of countless products. Among the unsung heroes in this precision-driven landscape are spline gauges—unsung yet indispensable tools that contribute to the flawless performance of gears and shafts. In this exploration, we delve into the world of spline gauges, unveiling their crucial role in manufacturing excellence.

Understanding Spline Gauges: The Backbone of Precision

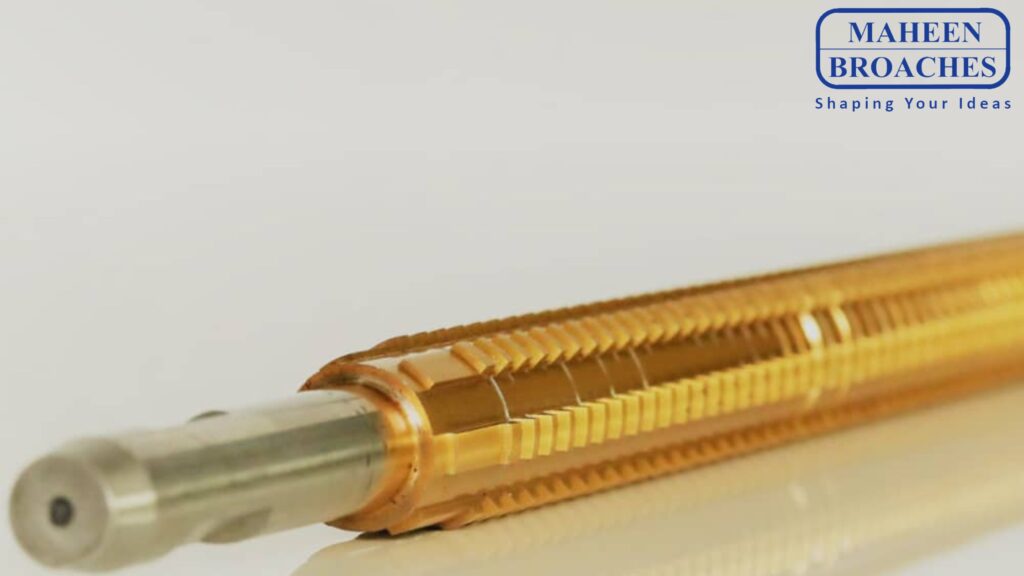

Spline gauges are specialized instruments designed for inspecting and ensuring the accuracy of splined components, such as gears and shafts. These components, featuring a series of ridges or teeth, are prevalent in various industries, including automotive, aerospace, and machinery manufacturing. Spline gauges come in various types, each tailored to specific spline profiles, ensuring a meticulous fit for diverse applications.

Precision in Every Groove: The Role of Spline Gauges in Manufacturing Quality

1. Accurate Measurement and Inspection:

Spline gauges serve as meticulous measuring tools, ensuring that the dimensions and profiles of splined components adhere to precise specifications. This accuracy is paramount in guaranteeing the seamless interaction of gears and shafts within a system.

2. Quality Control and Consistency:

Manufacturing processes demand consistency, and spline gauges act as guardians of quality control. By systematically inspecting each spline, these gauges uphold manufacturing standards, minimizing errors, and enhancing the overall reliability of end products.

3. Verification of Functional Integrity:

Beyond dimensions, spline gauges verify the functional integrity of splined components. This includes assessing factors such as proper tooth engagement, clearances, and tolerances, ensuring that the components will perform optimally under real-world conditions.

Applications Across Industries: Spline Gauges in Action

1. Automotive Precision:

In the automotive industry, spline gauges are instrumental in ensuring the flawless operation of transmission systems, steering mechanisms, and other crucial components. The precision they bring to gear manufacturing directly translates to smoother rides and enhanced vehicle performance.

2. Aerospace Reliability:

Aerospace applications demand the utmost precision and reliability. Spline gauges contribute to the manufacturing of gears and shafts used in aircraft propulsion systems, landing gear mechanisms, and other critical aerospace components.

3. Machinery and Beyond:

Spline gauges find applications in a myriad of machinery, from heavy industrial equipment to everyday appliances. Their role in maintaining precision and functionality extends to diverse sectors, impacting the efficiency of countless mechanical systems.

Looking Ahead: Innovations and Advancements in Spline Gauge Technology

As technology continues to evolve, so does the world of spline gauges. From advancements in materials and manufacturing techniques to the integration of digital technologies for more efficient inspections, the future holds exciting possibilities for enhancing the precision and capabilities of spline gauges.

Conclusion: Navigating Precision with Spline Gauges

In the intricate dance of gears and shafts, spline gauges stand as silent sentinels, ensuring each movement is executed with precision. As we navigate the world of manufacturing excellence, acknowledging the crucial role of spline gauges unveils the meticulous craftsmanship and dedication to precision that underlie the production of reliable and high-performance machinery across industries.