In the intricate world of machining, where precision is paramount, the humble spline mandrel stands as a testament to the marriage of art and science. These unassuming tools play a pivotal role in achieving machining excellence, particularly in the creation of splined shafts and gears. In this blog post, we’ll unravel the fascinating intricacies of spline mandrels, exploring their design, applications, and the precision craftsmanship they bring to machining mastery.

Understanding the Basics

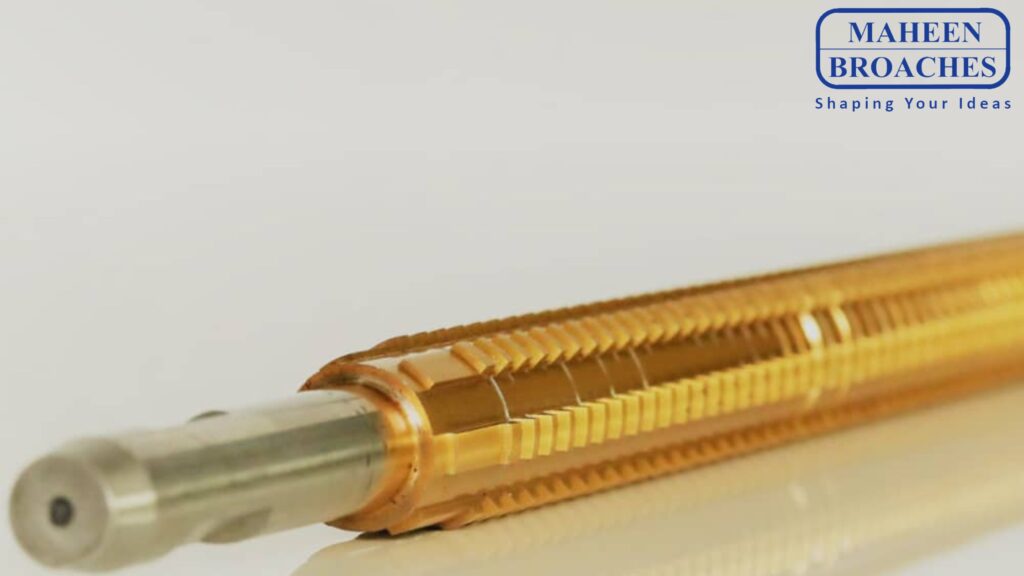

Spline mandrels are specialized devices designed to secure and align workpieces during machining processes. Their primary purpose is to ensure the accurate creation of splined components, which are integral to various mechanical systems. The meticulous design of these mandrels allows for the fixation of workpieces with precision, preventing any deviation during the machining journey.

Precision in Design

One of the key features that sets spline mandrels apart is their precision engineering. Crafted from high-quality materials such as hardened steel or alloy, these mandrels boast a robust design capable of withstanding the rigors of machining. Their carefully calculated dimensions and intricate shapes ensure a snug fit with the workpiece, minimizing any potential for misalignment or distortion.

Applications Across Industries

The versatility of spline mandrels extends across a spectrum of industries, from automotive and aerospace to manufacturing and beyond. Wherever intricate splined components are needed, these mandrels play a crucial role. Their application ensures that gears mesh seamlessly, shafts fit precisely, and the overall performance of machinery meets the stringent standards of modern engineering.

Achieving Tight Tolerances

In the realm of machining, achieving tight tolerances is a perpetual pursuit. Spline mandrels contribute significantly to this endeavor. By securely holding the workpiece in place, these mandrels enable machinists to execute intricate cuts and shaping with unparalleled accuracy. The result is a finished product that meets or exceeds the demanding specifications required by today’s industries.

Art and Science in Harmony

Machining is more than a technical process; it’s an art form. Spline mandrels embody this dual nature as they blend the scientific principles of engineering with the artistry of craftsmanship. Machinists skillfully wield these tools to transform raw materials into finely crafted components, where each spline is a testament to the precision and dedication invested in the process.

Conclusion In the world of machining, where precision is non-negotiable, spline mandrels emerge as unsung heroes. Their role in ensuring the accuracy and quality of splined components cannot be overstated. As we celebrate the precision craftsmanship inherent in machining mastery, let’s also pay homage to the indispensable contribution of spline mandrels—a true embodiment of precision, reliability, and excellence in the world of mac