When it comes to machining, precision is key. Every turn, every cut, every detail matters. And in this pursuit of perfection, reamers play a crucial role. In this comprehensive guide, we’ll delve into the world of reamers, exploring what they are, how they work, and why they’re essential in achieving precision in machining.

What are Reamers?

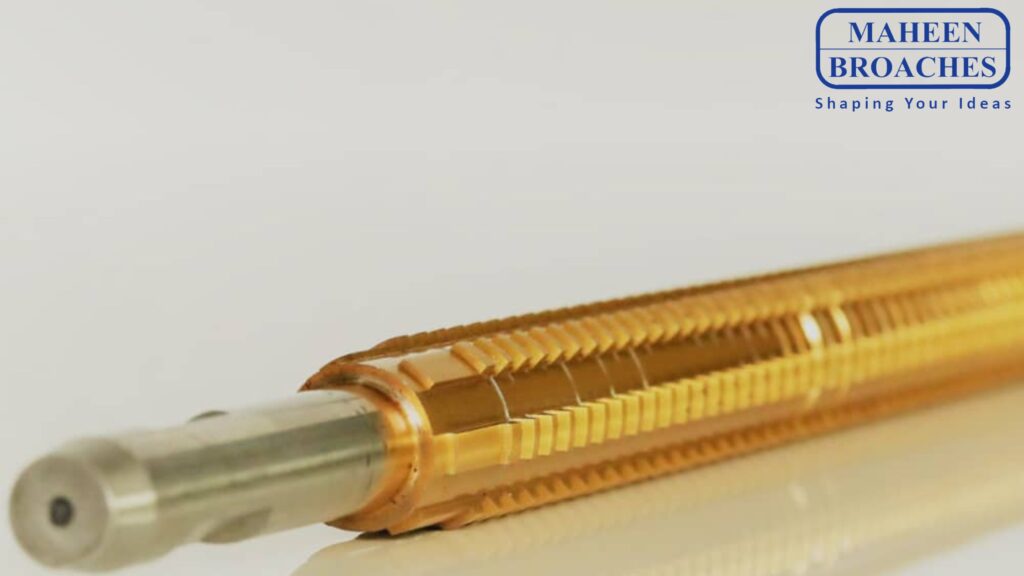

Reamers are cutting tools used in machining to enlarge and refine holes to precise dimensions. They come in various shapes and sizes, each designed for specific applications and materials. From simple hand reamers to complex carbide-tipped reamers, they all share the same purpose: to achieve accuracy and smoothness in bored holes.

How Reamers Work

Reamers function by removing small amounts of material from the inner surface of a hole. Unlike drills, which create holes, reamers refine them. They typically have multiple cutting edges and flutes, allowing them to remove material evenly as they rotate within the hole. This process results in a precisely sized and finished hole, meeting tight tolerances and surface finish requirements.

Types of Reamers

There are several types of reamers, each suited for different tasks and materials:

1. Hand Reamers: These are operated by hand and are suitable for smaller jobs or when precision is paramount.

2. Machine Reamers: Designed for use with machine tools, these reamers provide consistent and accurate results, often in high-volume production settings.

3. Spiral Flute Reamers: Ideal for blind-hole applications, these reamers have a spiral design that helps evacuate chips from the hole.

4. Straight Flute Reamers: These reamers are best suited for through-hole applications and provide excellent accuracy and surface finish.

5. Carbide Reamers: Known for their durability and long tool life, carbide reamers are often used in hard materials or high-speed machining operations.

Applications of Reamers

Reamers find application in various industries, including aerospace, automotive, manufacturing, and more. They are used for precision machining of components such as engine blocks, cylinders, bearings, and connecting rods, ensuring that critical parts fit together seamlessly.

Tips for Using Reamers

To get the most out of reamers and ensure optimal performance, consider the following tips:

– Always use the correct type and size of reamer for the job.

– Secure workpieces properly to prevent movement during reaming.

– Use cutting fluid to lubricate and cool the cutting edges, prolonging tool life and improving surface finish.

– Monitor the reaming process closely to maintain tight tolerances and avoid over-sizing the hole.

Conclusion

In the world of machining, precision is non-negotiable. Reamers are indispensable tools that help achieve the accuracy and quality required for critical components in various industries. By understanding their types, applications, and best practices for use, you can master precision machining and elevate the quality of your work to new heights.