In the realm of precision machining, where intricacy meets innovation, one tool stands out for its ability to shape materials with unparalleled accuracy and efficiency — the profile broach. As a cornerstone in the world of manufacturing, profile broaches play a pivotal role in crafting components with intricate profiles, offering a level of precision and versatility that sets them apart. In this exploration, we delve into the world of profile broaches, unraveling the secrets behind their ability to shape excellence.

1. Precision Redefined: The Anatomy of Profile Broaches

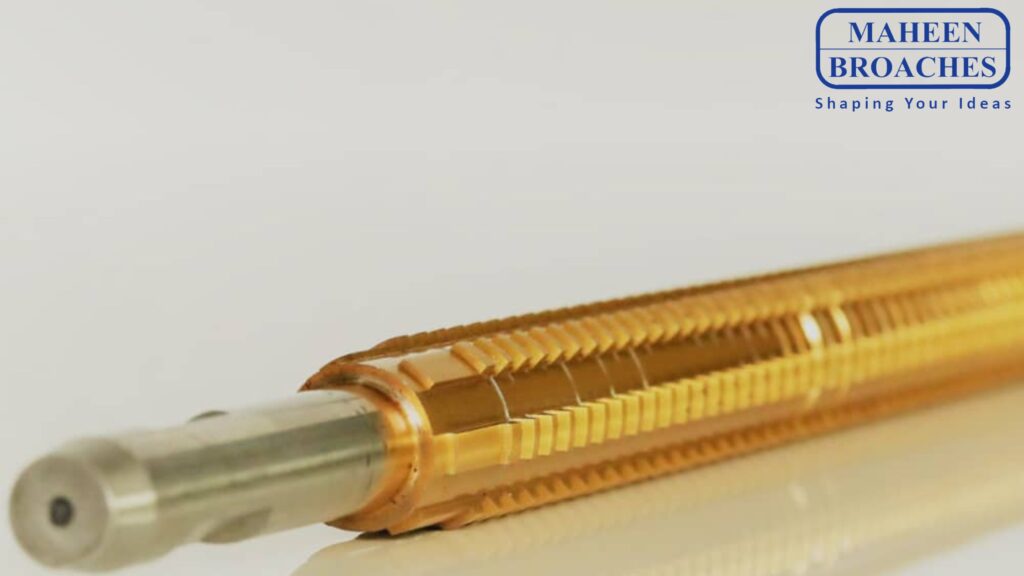

Profile broaches are precision cutting tools designed for creating specific shapes, contours, and profiles in workpieces. Crafted with meticulous attention to detail, these tools consist of a series of teeth or cutting edges arranged in a specific pattern, allowing them to replicate intricate shapes with impeccable precision. Whether it’s internal keyways, splines, or complex surface profiles, profile broaches excel at shaping components to exact specifications.

2. Versatility in Action: A Tool for Varied Profiles

One of the defining features of profile broaches is their remarkable versatility. These tools can be engineered to suit a wide range of profiles, adapting to the unique requirements of different components. From gears and automotive components to aerospace parts, profile broaches are the go-to solution for manufacturing industries where precision and adaptability are paramount.

3. The Broaching Process Unveiled: How Profile Broaches Work

The broaching process involving profile broaches is a fascinating journey in precision machining. A workpiece is secured, and the broach is guided through or across it, progressively removing material in a controlled manner. This process ensures that intricate profiles are faithfully reproduced, achieving the desired shape with exceptional accuracy. The efficiency of this process is a key reason behind the widespread use of profile broaches in modern manufacturing.

4. Crafting Efficiency: Advancements in Profile Broach Technology

As technology advances, so does the efficiency of profile broaches. Modern manufacturing demands faster production cycles and higher precision, prompting continuous innovation in broaching technology. Carbide inserts, coatings for enhanced durability, and advanced machine controls are just a few examples of how profile broaches are evolving to meet the evolving needs of the industry.

5. Applications Across Industries: Where Precision Matters Most

The applications of profile broaches span across a multitude of industries. In automotive manufacturing, they craft gears and drive components. In aerospace, they shape intricate parts with exacting specifications. From medical devices to consumer electronics, profile broaches leave their mark wherever precision and customization are prerequisites.

6. Achieving Sustainability: Profile Broaches in Modern Manufacturing

Beyond precision and versatility, profile broaches contribute to sustainability in manufacturing. By optimizing material usage and reducing waste through precise shaping, these tools align with the growing emphasis on eco-friendly practices in the industry.

Conclusion: Shaping Tomorrow with Profile Broaches

In the intricate dance of modern manufacturing, profile broaches emerge as the maestros, orchestrating the symphony of precision, versatility, and efficiency. As industries continue to push the boundaries of what’s possible, these cutting-edge tools remain at the forefront, shaping excellence and leaving an indelible mark on the components that propel our world forward. In the hands of skilled machinists, profile broaches become instruments of craftsmanship, transforming raw materials into works of engineering artistry.