In the intricate world of precision machining, where every cut counts, the pull broach emerges as a true hero. A tool designed for power and precision, the pull broach plays a pivotal role in shaping components with meticulous accuracy. In this exploration, we take a profound dive into the world of pull broaches, uncovering the remarkable power and precision that sets them apart in the realm of manufacturing.

1. The Pull Broach Unveiled: A Master of Precision Machining

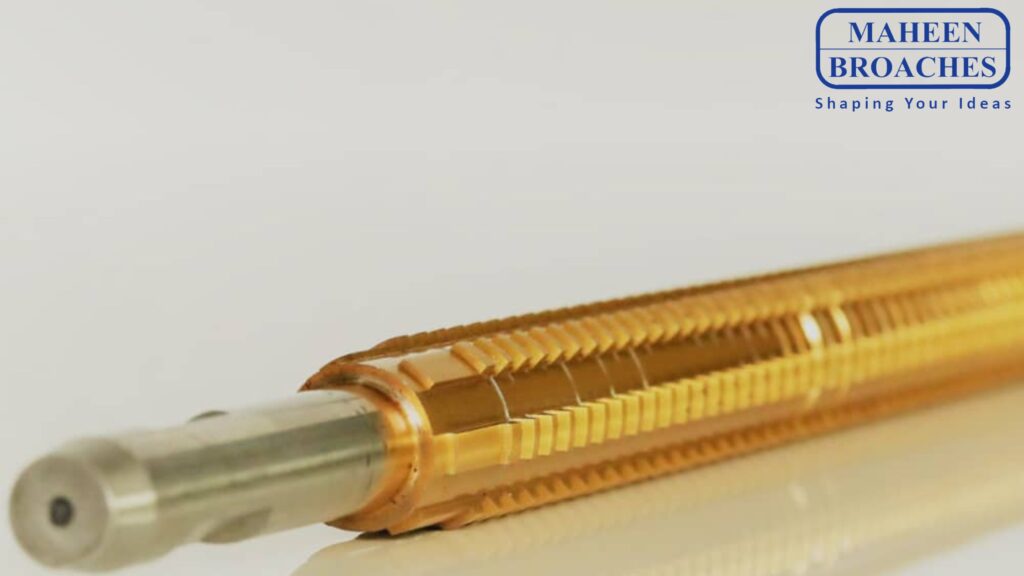

At its essence, a pull broach is a cutting tool that excels in producing keyways, splines, and other intricate profiles in a workpiece. Its design allows for a controlled, linear pull motion, ensuring a steady and precise cut. This makes pull broaches particularly effective in creating internal shapes with tight tolerances.

2. Pulling Power: Understanding the Mechanics of Pull Broaches

The mechanics behind the pull broach are a testament to its pulling power. The broach is pulled through the workpiece, removing material incrementally with each pass. This controlled pulling motion, often assisted by a broaching machine, ensures a smooth and precise cutting action. The ability to handle tougher materials and produce accurate profiles makes pull broaches indispensable in various manufacturing processes.

3. Precision in Every Pull: Crafting Intricate Profiles

Pull broaches are renowned for their ability to craft intricate profiles with exceptional precision. Whether it’s internal gears, keyways in shafts, or complex surface features, the pull broach is designed to replicate these shapes faithfully. Machinists rely on the tool’s accuracy to meet stringent specifications, ensuring that components fit seamlessly into larger assemblies.

4. Advancements in Pull Broach Technology: Powering Progress

As with any cutting tool, pull broaches have evolved with technological advancements. Modern pull broaches often feature carbide inserts for enhanced durability and cutting efficiency. Additionally, improvements in coatings and materials contribute to a longer tool life, reducing the frequency of tool changes and increasing overall productivity.

5. Tailoring to Precision: Pull Broaches in Custom Manufacturing

The adaptability of pull broaches extends to custom manufacturing scenarios. These tools can be tailored to specific profiles and sizes, allowing manufacturers to create unique components tailored to their precise needs. From automotive parts to specialized machinery components, pull broaches play a crucial role in the production of bespoke elements.

6. Pull Broaches in Action: Applications Across Industries

The versatility and precision of pull broaches find applications across a spectrum of industries. In automotive manufacturing, they shape keyways in crankshafts; in aerospace, they create intricate profiles in turbine components. The medical industry relies on pull broaches for crafting precision instruments, showcasing the tool’s diverse applications.

Conclusion: Pulling Together Precision and Power

In the symphony of precision machining, the pull broach takes center stage, pulling together the elements of accuracy and power. As industries demand ever-increasing precision and efficiency, pull broaches stand ready to meet the challenge. From their controlled pulling motion to the intricacies of their designs, these tools exemplify the artistry that is precision machining, shaping components with the utmost accuracy and leaving an indelible mark on the world of manufacturing. In the hands of skilled machinists, pull broaches become instruments of crafting excellence, pulling together the intricate details that define the cutting edge of manufacturing precision.