Broaching is a precision machining process used across various industries to create complex shapes, cut keyways, and produce precise internal features in components. The success of broaching heavily relies on the quality of the tools employed. While it might be tempting to opt for more budget-friendly options, investing in high-quality broaching tools offers numerous advantages that can significantly impact your machining operations. In this blog, we’ll delve into the reasons why high-quality broaching tools matter and the benefits they bring to the table.

1. Precision and Consistency

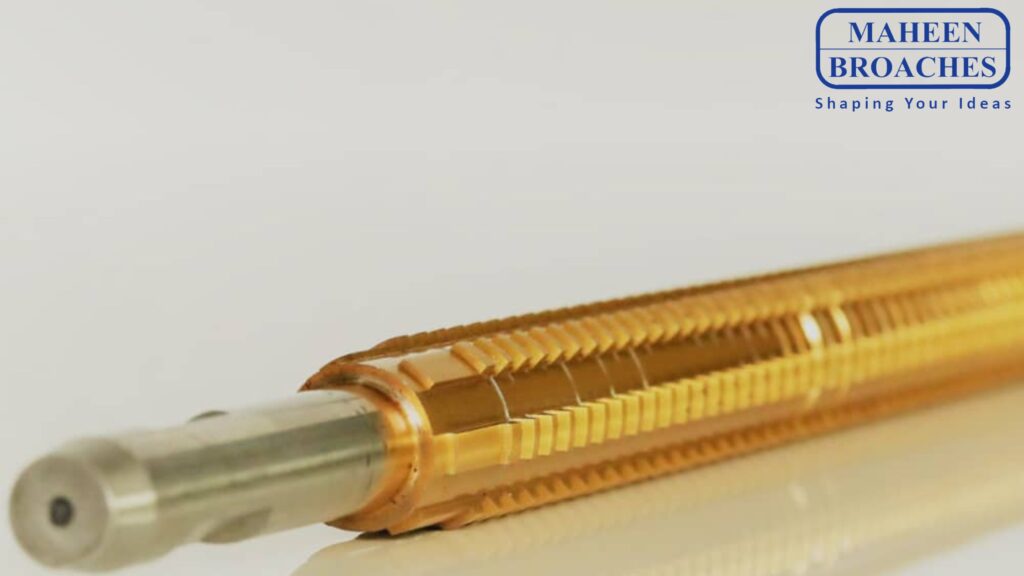

Precision is paramount in machining operations, and broaching is no exception. High-quality broaching tools are engineered with meticulous attention to detail, ensuring precise cuts and consistent results. Whether you’re shaping internal keyways, splines, or other intricate features, premium tools guarantee the accuracy you need, reducing the risk of errors and rework.

2. Enhanced Durability

Quality comes hand in hand with durability. High-quality broaching tools are constructed from robust materials and undergo stringent manufacturing processes to withstand the demands of heavy use. This durability not only extends the tool’s lifespan but also reduces the frequency of replacements, ultimately saving you time and money in the long run.

3. Improved Surface Finish

The finish quality of your machined components matters, especially in industries where aesthetics or functionality are critical. Premium broaching tools are designed to create smoother and finer surface finishes, reducing the need for additional finishing processes or polishing, thus saving you time and resources.

4. Reduced Tool Wear

Lower-quality broaching tools tend to wear out more quickly, which can lead to tool breakage and increased downtime. High-quality tools, on the other hand, exhibit superior wear resistance, ensuring longer tool life and reduced maintenance hassles.

5. Increased Productivity

When you invest in high-quality broaching tools, you invest in efficiency. Premium tools can often handle higher cutting speeds and feeds, allowing you to complete your machining tasks faster without compromising on quality. This increased productivity translates to cost savings and quicker turnaround times for your projects.

6. Minimized Downtime

Tool failures or frequent replacements can result in significant downtime for your machining operations. High-quality broaching tools are less prone to breakage or wear, minimizing unplanned interruptions and ensuring your production schedule remains on track.

7. Consistent Tool Performance

Reliability is a key attribute of high-quality broaching tools. Premium tools maintain consistent performance throughout their lifespan, reducing the need for constant adjustments and fine-tuning during machining operations.

8. Quality Assurance

Many industries, such as aerospace, automotive, and medical device manufacturing, require strict adherence to quality standards. Investing in high-quality broaching tools helps you meet these standards with confidence, ensuring your components meet the necessary specifications and regulations.

Conclusion

In the world of machining, the phrase “you get what you pay for” couldn’t be truer. High-quality broaching tools may require a slightly higher initial investment, but the benefits they offer in terms of precision, durability, productivity, and overall machining quality far outweigh the costs. When you choose premium broaching tools, you’re not just buying a tool; you’re investing in the success and efficiency of your machining operations. So, when it comes to broaching, make the smart choice—choose high-quality broaching tools and experience the difference they can make in your production processes.