Introduction:

When it comes to precision machining, having the right tools is essential. Broaching tools play a crucial role in achieving accurate and efficient metal cutting operations. If you’re in search of top-notch broaching tools for sale, this blog is here to guide you. We will explore the importance of high-quality broaching tools, the different types available, and where to find reliable suppliers offering a wide range of options to meet your machining needs.

1. Understanding Broaching Tools:

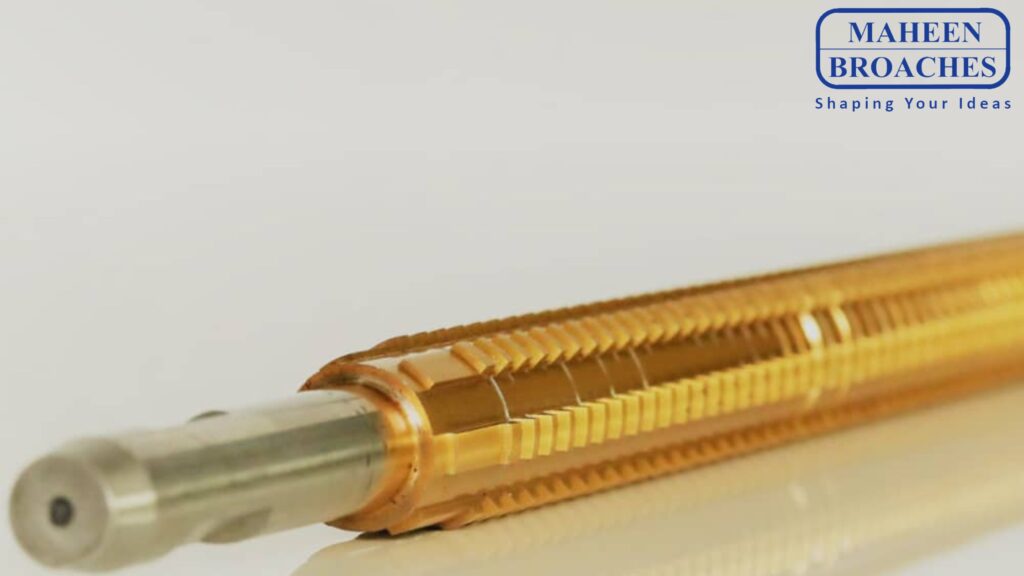

Gain a comprehensive understanding of broaching tools and their significance in machining processes. Learn about the various components of broaching tools, their function, and the types of materials they are commonly used on.

2. Types of Broaching Tools:

Explore the different types of broaching tools available in the market. From keyway broaches and spline broaches to surface broaches and internal broaches, discover the specific applications and advantages of each type.

3. Features of High-Quality Broaching Tools:

Uncover the key features that define high-quality broaching tools. Learn about the importance of tool material, cutting edge geometry, coatings, and other factors that contribute to the performance and longevity of broaching tools.

4. Benefits of Using High-Quality Broaching Tools:

Discover the advantages of investing in high-quality broaching tools for your machining operations. From improved accuracy and surface finish to enhanced productivity and reduced downtime, learn how top-notch broaching tools can positively impact your overall manufacturing process.

5. Factors to Consider When Selecting Broaching Tools:

Get insights into the factors to consider when choosing broaching tools for your specific machining requirements. Explore aspects such as tool geometry, size range, material compatibility, and cost-effectiveness to make informed decisions.

6. Reliable Suppliers of Broaching Tools:

Find out where to source reliable suppliers offering a wide range of broaching tools for sale. Explore reputable manufacturers and distributors known for their commitment to quality, customer support, and competitive pricing.

7. Customization Options for Broaching Tools:

Discover the possibilities of customizing broaching tools to suit your unique machining needs. Learn about the availability of tailor-made solutions, including special sizes, shapes, and coatings that can optimize your cutting operations.

8. Maintenance and Care for Broaching Tools:

Understand the importance of proper maintenance and care for broaching tools to maximize their lifespan and performance. Explore best practices for tool cleaning, lubrication, and storage to ensure consistent and reliable results.

9. Industry Applications of Broaching Tools:

Explore the wide range of industries that benefit from the use of broaching tools. From automotive and aerospace to medical and energy sectors, learn about the diverse applications where broaching tools excel.

10. Future Trends in Broaching Technology:

Stay updated on the latest advancements and future trends in broaching technology. Explore innovations such as tool coatings, cutting edge geometries, and automation that are shaping the future of broaching tools.

Conclusion:

Investing in high-quality broaching tools is a wise decision to enhance your machining efficiency and achieve precise metal cutting results. By understanding the different types of broaching tools, selecting reliable suppliers, and considering customization options, you can optimize your machining processes and stay ahead in the competitive manufacturing landscape. Explore the possibilities and elevate your machining capabilities with top-notch broaching tools that meet your unique requirements. Contact Maheen Broaches for buying broaching tools in India.