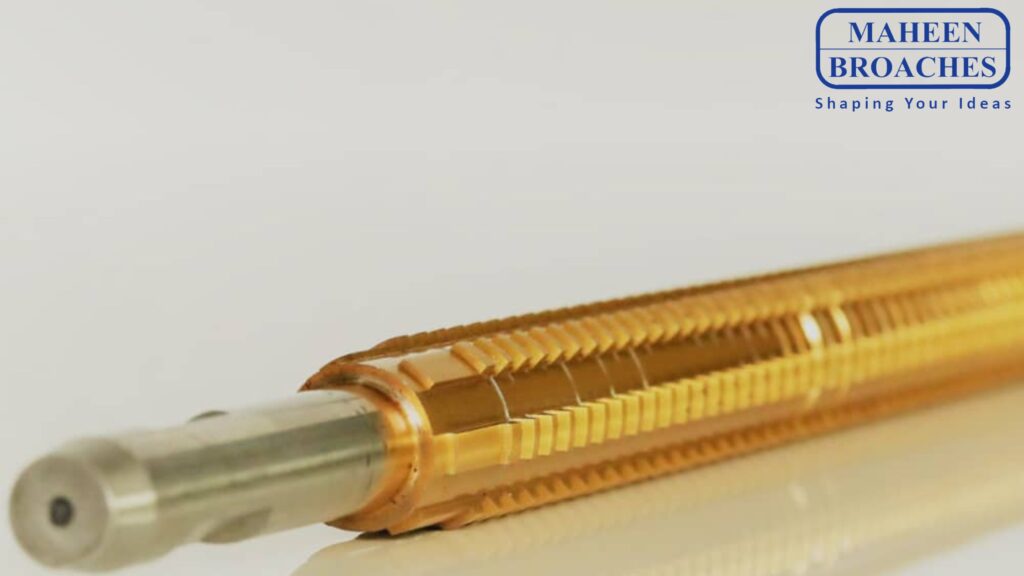

In precision machining, every component plays a vital role in achieving accuracy and efficiency. One such crucial tool is the mandrel, a work holding device that ensures secure positioning and stability during operations like broaching, grinding, and turning. Investing in high-quality mandrels is essential for maintaining precision, reducing errors, and improving overall productivity.

The Role of Mandrels in Broaching and Machining

Mandrels are used to hold a workpiece securely while machining operations are performed. Their primary functions include:

- Ensuring Stability: Preventing movement or shifting of the workpiece during machining.

- Maintaining Precision: Allowing for accurate material removal and dimensional consistency.

- Enhancing Efficiency: Reducing setup time and ensuring seamless operation.

Why Quality Mandrels Matter

Using high-quality mandrels offers several benefits that directly impact machining performance and product quality.

1. Superior Accuracy and Tolerance Control

Precision machining requires extreme accuracy, and a poorly manufactured mandrel can lead to deviations. High-quality mandrels provide excellent tolerance control, ensuring that every broached or machined part meets exact specifications.

2. Increased Durability and Longevity

Mandrels made from premium materials such as hardened steel or carbide offer superior durability, reducing wear and tear. Investing in robust mandrels minimizes replacement costs and extends tool life, making them a cost-effective solution in the long run.

3. Enhanced Surface Finish

A secure workpiece results in a smoother machining process, reducing vibrations and tool chatter. This leads to an improved surface finish, essential for applications in automotive, aerospace, and precision engineering industries.

4. Compatibility with Various Applications

Different machining processes require different mandrel types. High-quality mandrels are designed for versatility, accommodating a wide range of workpieces and machining techniques such as:

- Spline broaching

- Internal and external grinding

- Turning and milling

- Gear cutting

5. Reduced Setup Time and Increased Productivity

A well-designed mandrel simplifies the work holding process, leading to faster setup times and increased throughput. This improves overall production efficiency, allowing manufacturers to meet deadlines without compromising on quality.

Choosing the Right Mandrel for Your Needs

When selecting a mandrel, consider the following factors:

- Material composition – Opt for hardened steel or carbide for longevity.

- Design type – Fixed, expansion, or hydraulic mandrels based on the application.

- Tolerance requirements – Ensure the mandrel provides the required precision for your machining process.

Conclusion

Quality mandrels are an essential component of efficient broaching and machining operations. They improve accuracy, durability, and productivity while ensuring a high-quality finish on machined parts. At Maheen Broaches, we offer precision-engineered mandrels designed to meet the highest industry standards.

Looking for premium-quality mandrels for your machining needs? Contact Maheen Broaches today to explore our range of precision work holding solutions.