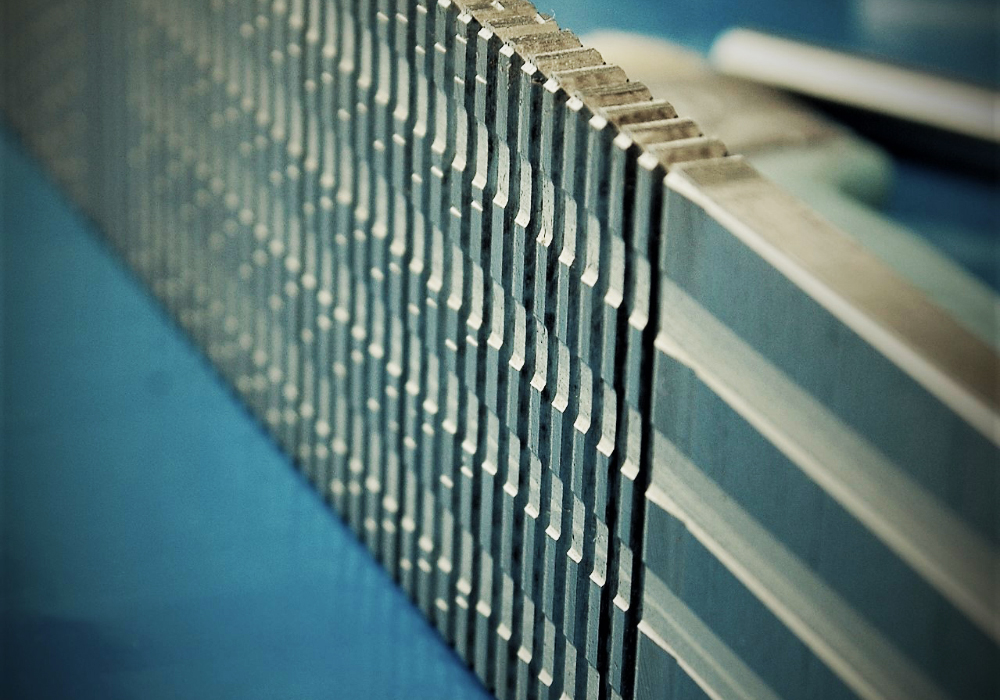

External broaches removes material from the exterior of the workpiece and is referred to as surface broaching. Like the internal broaching tool, the teeth of an external broaching tool progressively increase. External broaching uses a guided ram with a broach holding fixture. The force of the cutting is transferred to the ram along the length of the broach. We manufacture external broaches using world grade material like HSS M2, M35, M42, ASP2030, ASP2052 etc. having maximum overall length of broach is 1500 mm. External broaches are flat surfaces and form surfaces. With flat surface broaching, the tool passes over the workpiece to produce a desired surface. The form surface broaching process is designed to produce different contours and shapes, which include serrated, angular spline, gear forms, racks, keyways and special profiles

Steering Rack Broaches

Flat and Form Broaches

Lock Broaches

Height Broaches

Gear Shifter Broaches